In the world of maritime operations, the efficiency and safety of mooring and anchoring play a critical role. Ships, boats, and offshore platforms rely on robust mooring systems to secure their position and stability, especially in adverse weather conditions. Hydraulic mooring winch systems have emerged as an indispensable component in this domain, offering unmatched power, control, and reliability. In this article, we will delve into the world of hydraulic mooring winch systems, exploring their components, advantages, applications, and significance in modern maritime operations.

The Anatomy of a Hydraulic Mooring Winch System

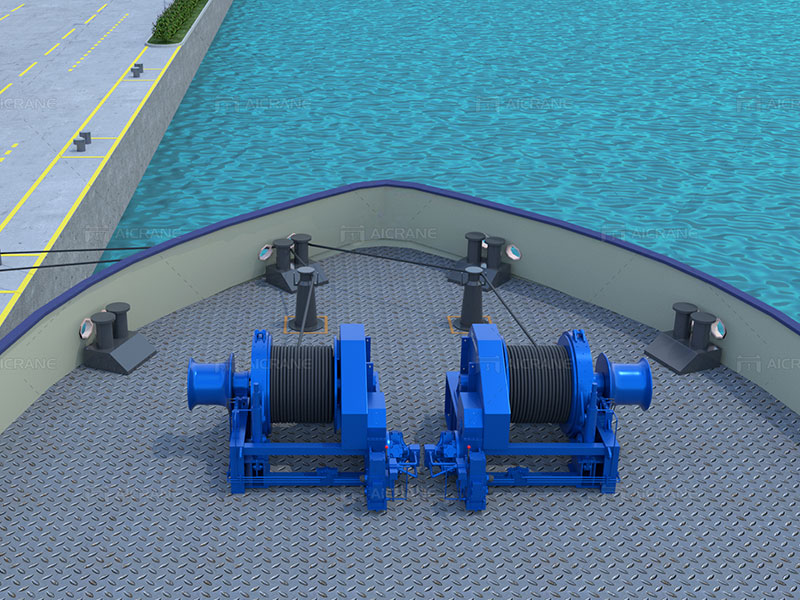

A hydraulic mooring winch system is a sophisticated piece of machinery designed to control the deployment and retrieval of mooring lines or anchor chains. It consists of several key components that work in tandem to ensure the efficient and safe mooring of vessels. Here’s a breakdown of these essential components:

Hydraulic Power Unit (HPU): At the heart of the system lies the hydraulic power unit, which generates the necessary force to operate the hydraulic mooring winch system. This unit typically includes a hydraulic pump, motor, reservoir, and control valves. It converts mechanical power into hydraulic pressure, allowing for precise control over the winch’s operations.

Winch Drum: The winch drum is the central component responsible for winding and unwinding the mooring line or anchor chain. It is driven by the hydraulic motor and is equipped with flanges to prevent the line from slipping off during operation.

Control Panel: The control panel serves as the operator’s interface with the hydraulic mooring winch system. It provides controls for adjusting line tension, direction, speed, and emergency stop functions. Modern systems often incorporate advanced touchscreens and remote control capabilities for increased convenience and safety.

Brake System: To maintain tension in the mooring line or anchor chain, a hydraulic mooring winch system is equipped with a brake mechanism. This brake ensures that the line remains securely in place when not actively being deployed or retrieved.

Advantages of Hydraulic Mooring Winch Systems

Power and Precision: Hydraulic systems offer exceptional power and precision, allowing operators to exert precise control over the tension and movement of mooring lines. This is crucial for accommodating various vessel sizes and environmental conditions.

Reliability: Hydraulic mooring winch systems are known for their reliability and durability. They are capable of withstanding harsh marine environments, including saltwater exposure and extreme weather conditions.

Safety: These systems are designed with safety in mind. They feature emergency stop functions and fail-safe mechanisms to prevent accidents and ensure the well-being of operators and vessels.

Efficiency: Hydraulic systems are highly efficient, with minimal energy loss during operation. This efficiency translates to reduced operational costs and a smaller environmental footprint.

Applications of Hydraulic Mooring Winch Systems

Shipping Industry: Hydraulic mooring winch systems are widely used in the shipping industry to secure vessels in ports, docks, and terminals. They are essential for the safe loading and unloading of cargo and passengers.

Offshore Oil and Gas Platforms: Offshore platforms require robust mooring systems to stay in position despite strong ocean currents and adverse weather conditions. Hydraulic mooring winch systems provide the necessary reliability and control.

Tugboats and Workboats: Tugboats and workboats rely on mooring winches to assist larger vessels, perform towing operations, and maintain station-keeping during various tasks.

Research Vessels: Research vessels, often operating in remote and challenging environments, depend on hydraulic mooring winch systems to deploy and recover scientific equipment, such as ROVs (Remotely Operated Vehicles) and oceanographic instruments.

Fishing Vessels: Commercial fishing vessels use hydraulic mooring winches to anchor and secure their positions during fishing operations, ensuring they remain stable in turbulent waters.

Significance in Modern Maritime Operations

The evolution of hydraulic mooring winch systems has revolutionized modern maritime operations in several ways:

Enhanced Safety: The precise control and safety features of hydraulic systems significantly reduce the risk of accidents during mooring and anchoring procedures. This translates to safer working conditions for crew members and the protection of valuable vessels.

Increased Efficiency: Hydraulic mooring winch systems streamline operations by reducing manual labor and increasing the speed and accuracy of mooring processes. This efficiency contributes to faster turnaround times for vessels in ports and improved overall productivity.

Environmental Impact: The energy efficiency of hydraulic systems aligns with the maritime industry’s growing emphasis on reducing its environmental footprint. Lower energy consumption not only saves costs but also reduces greenhouse gas emissions.

Versatility: These systems are adaptable to a wide range of vessel sizes and types, making them a versatile choice for various maritime applications.

Conclusion

Hydraulic mooring winch systems have become indispensable in modern maritime operations due to their power, precision, and reliability. From securing vessels in ports to supporting offshore platforms and aiding research vessels, these systems play a crucial role in ensuring the safety and efficiency of maritime activities. As technology continues to advance, we can expect even more sophisticated and efficient marine winch systems to further transform the maritime industry, making it safer, more sustainable, and more productive than ever before.